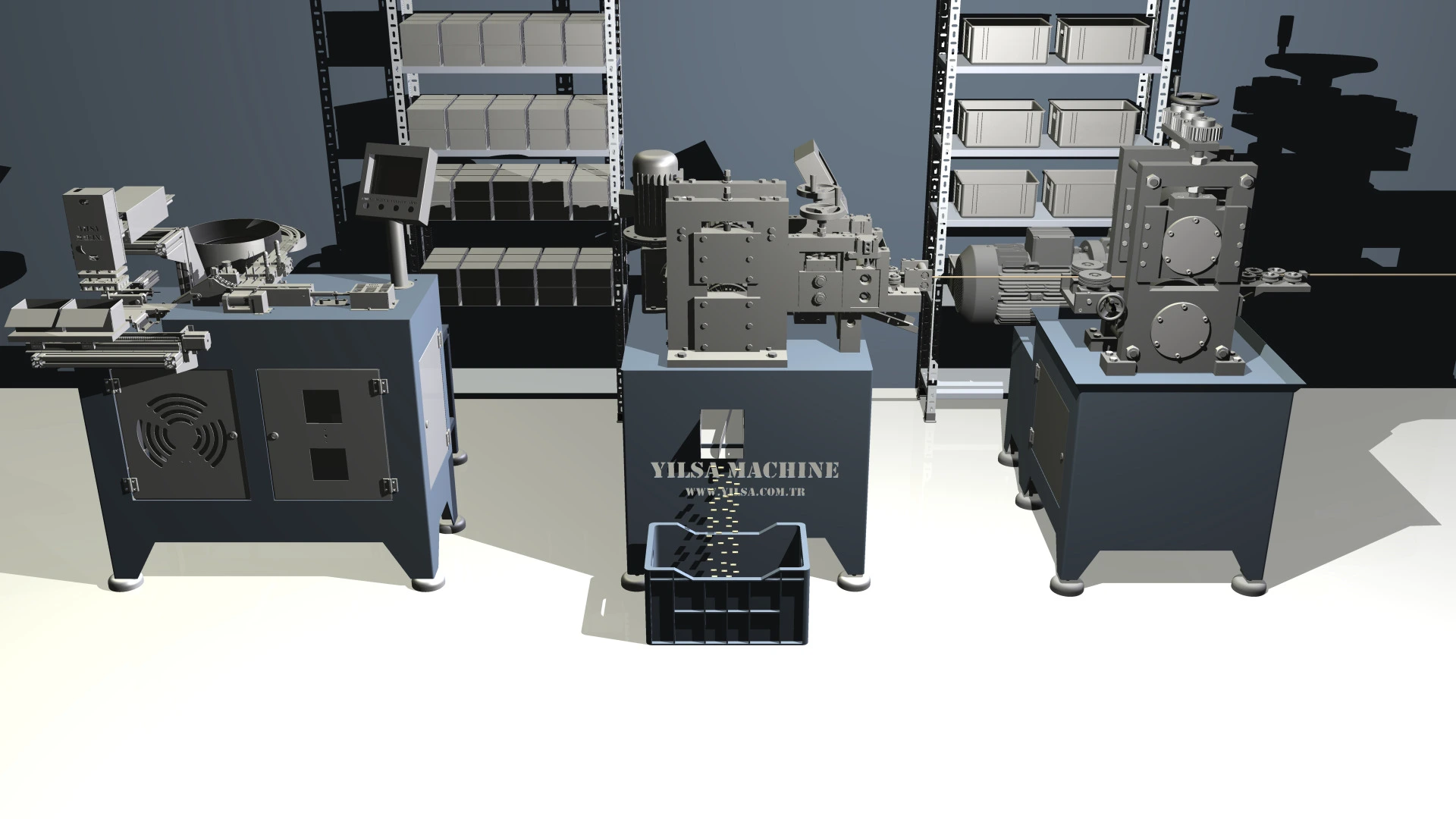

High-Speed Wheel Weight Production Machine

Achieve unmatched production speeds of 100,000 pieces per hour with our advanced rotary punch technology

Key Features & Technical Specifications

Chopping and marking machine

Chopping and marking machine, used to manufacture wheel weights. Produces 5 gr stick-on wheel weights by cutting 19 mm long pieces from 11.5 mm wide rolled metal strip. 19 mm length is fixed. Steel Balancing Weights are produced in the desired weight by changing the width of the strip. A 23 mm wide strip is used to produce 10 gr. Desired gr and oz values can be obtained by using different strip widths.

During production, automotive wheel weights are marked with the desired brand logo and product weights descriptions.

High-precision Wheel Weights have a precision of ±0.5 gr. The machine can be set to 5 gr - 5 gr or 5 gr - 10 gr. SAE 1006/1008 type flat wire or slit steel sheets can be used as raw material.

As trusted wheel weight machine manufacturers, our systems deliver accuracy and speed, competing with top brands like Wegmann Automotive and BendPak USA.

| Production Specifications | Machine Specifications |

|---|---|

| Production Capacity | 100,000 pcs/hour (double feed) |

| Energy Consumption | 1.37 kWh per 100,000 pieces |

| Strip Width (5g) | 11.5 mm |

| Cut Length | 19 mm fixed |

| Raw Material | St37 steel strip in roll |

| Material Thickness | ~3 mm |

Advanced Technology vs Traditional Methods

Rotary Punch Technology

- 100,000 pieces/hour production speed

- 83,300 pieces/kWh energy efficiency

- Continuous rotary motion for smooth operation

- Self-feeding mechanism

- Burr-free, precise cuts

Traditional Press Systems

- 25,000 pieces/hour production speed

- 20,800 pieces/kWh energy efficiency

- Intermittent motion causing vibration

- Requires external feeding unit

- Burrs and cutting angle distortion

Core of Your Production Line

The Wheel Weights Chopping and Marking Machine stands as the cornerstone of efficient wheel weight manufacturing. As the central component in the production line, it transforms raw material into precisely cut and clearly marked weights, setting the foundation for all subsequent processing steps.

Advanced Operation System

The machine's dual-drum design incorporates both cutting and marking functions in a single, streamlined process. While the primary drums handle precise cutting without material waste, the integrated marking drums simultaneously imprint weight values and brand information with exceptional clarity. This synchronized operation ensures consistent quality across high-volume production runs.

Superior Production Benefits

The rotary punch technology delivers three key advantages over traditional press systems:

- Energy efficiency: Consuming just 1.37 kWh per 100,000 pieces, representing an 80% reduction in energy usage

- Quality consistency: Produces burr-free cuts with clear markings through continuous rotational force

- Space optimization: Compact design with vertical punch mechanism requires minimal floor space while maintaining maximum output

Integration & Automation

The machine seamlessly connects with both upstream wire flattening and downstream taping processes. Its self-feeding mechanism eliminates the need for additional feeding units, while the precision-controlled output ensures smooth transition to subsequent processing stages. The entire system is managed through an advanced Delta PLC control system with a 7" display interface, enabling real-time monitoring and adjustment of production parameters.

Contact Us

Transform your wheel weights production with our innovative solutions. Get in touch with us to discuss your requirements and discover how our solutions can benefit your business.

Contact us to become our representatives!