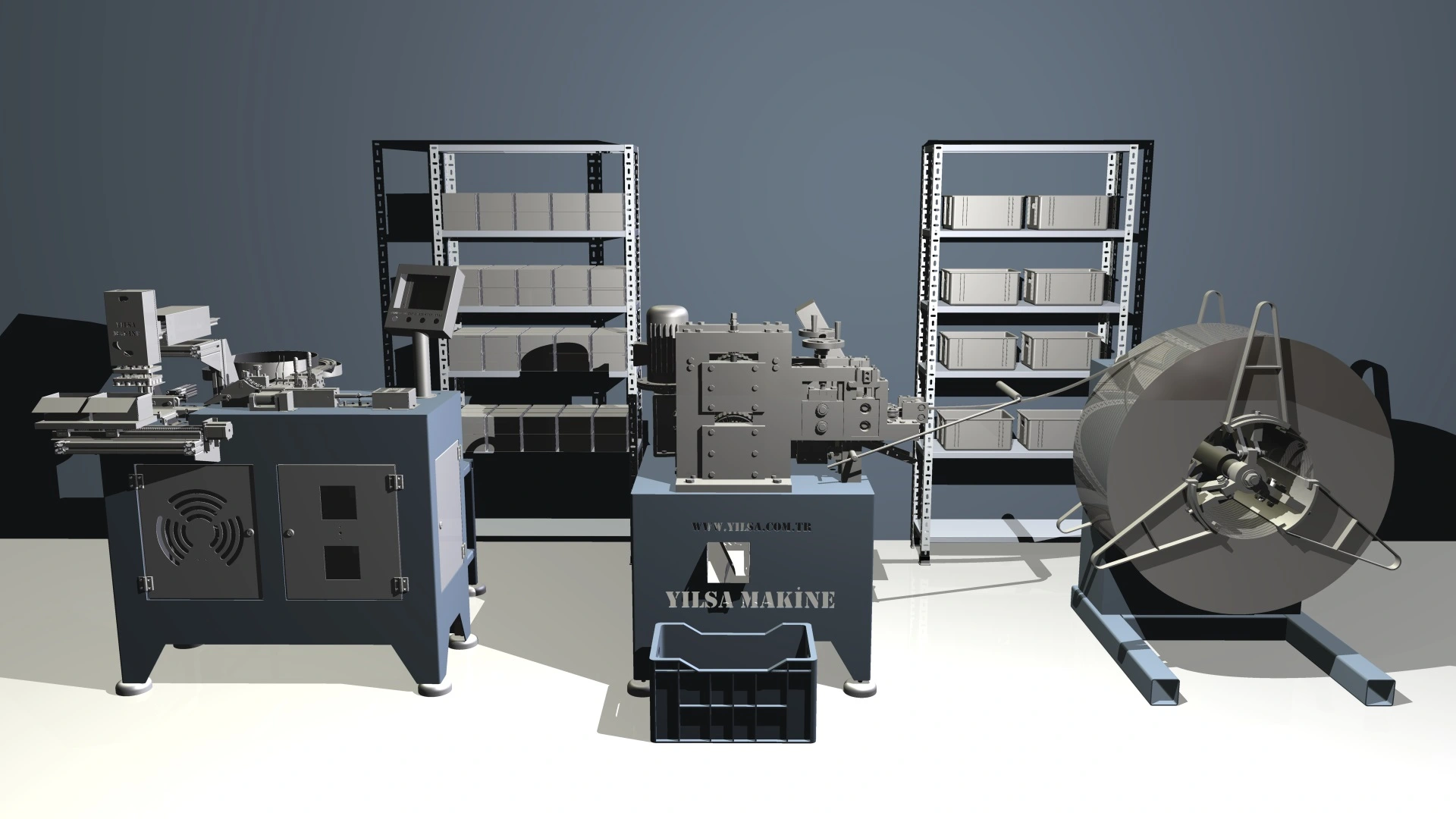

Comprehensive Decoiling Solutions

Experience superior coil processing with our comprehensive range of decoiler machines, featuring capacities from 300kg to 10,000kg. Advanced technology meets precision engineering for optimal material handling across all industries.

Key Features & Technical Specifications

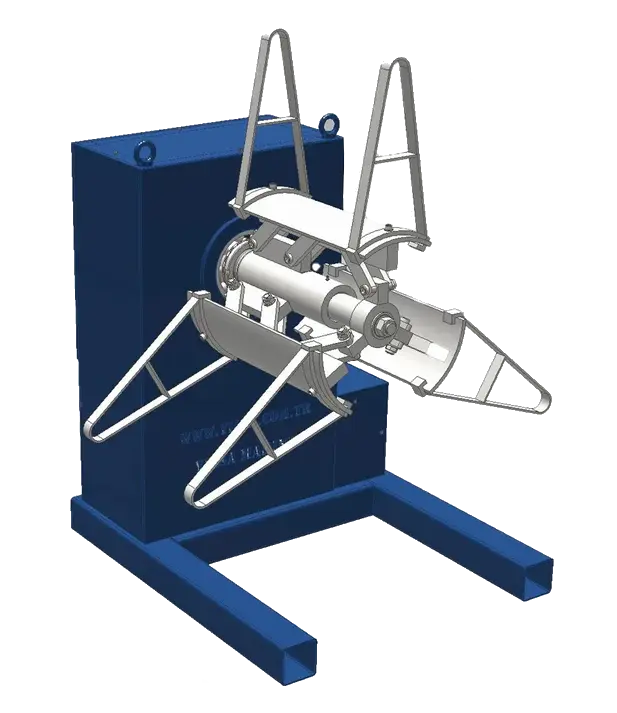

Decoiler Machine

YILSA Coil Feeders & Uncoilers machines deliver superior performance and operate reliably across a wide range of applications. From light-duty tasks to heavy industrial use, we offer versatile solutions.

Our product range extends from manual decoiler machine to manual/hydraulic decoiler machine. Additionally, for wire rod straightening and cutting machines, we manufacture both Horizontal Decoiler and Pallet Decoiler machines.

We also produce sheet metal decoilers for press feeding systems.

| Standard Product Range | Wheel Weight Series |

|---|---|

| Models | RL_300-10000 |

| Capacity Range | 300-10 000 kg |

| Strip Width | 200-1200 mm |

| Max Outer Diameter | 1000-1400 mm |

| Inner Diameter Range | 300-550 mm |

| Drive System | Mechanical/Hydraulic |

| Max Speed | 40 m/min |

| Power Range | 0.25-5 kW |

The Starting Point of Production

The Decoiler Machine marks the crucial first step in the wheel weight production line. It efficiently unwinds large coils of raw material, preparing it for subsequent processing stages like wire flattening and cutting. This initial stage is vital for ensuring a smooth and continuous flow throughout the entire manufacturing process.

Key Features & Design

Our Decoiler Machines are engineered for reliability and ease of use. They feature robust construction to handle various coil weights and sizes, along with precise control mechanisms to manage unwinding speed and tension. This ensures the material is fed consistently and without damage into the next stage of production.

Available Series

- Light Series: Ideal for smaller production scales and lighter coil materials.

- Medium Series: A versatile option balancing capacity and footprint for moderate production needs.

- Heavy Series: Designed for high-volume manufacturing, capable of handling large and heavy coils.

Standard Equipment

Each Decoiler Machine comes equipped with standard features necessary for efficient operation, including safety guards, adjustable speed controls, and durable coil support systems. Optional upgrades may be available depending on the specific series and application requirements.

Applications

While primarily used as the starting point for our adhesive wheel weight production line, our Decoiler Machines are adaptable and can be integrated into various manufacturing processes that require controlled unwinding of coiled materials, such as sheet metal processing or wire forming industries.

Contact Us

Transform your wheel weights production with our innovative solutions. Get in touch with us to discuss your requirements and discover how our solutions can benefit your business.

Contact us to become our representatives!