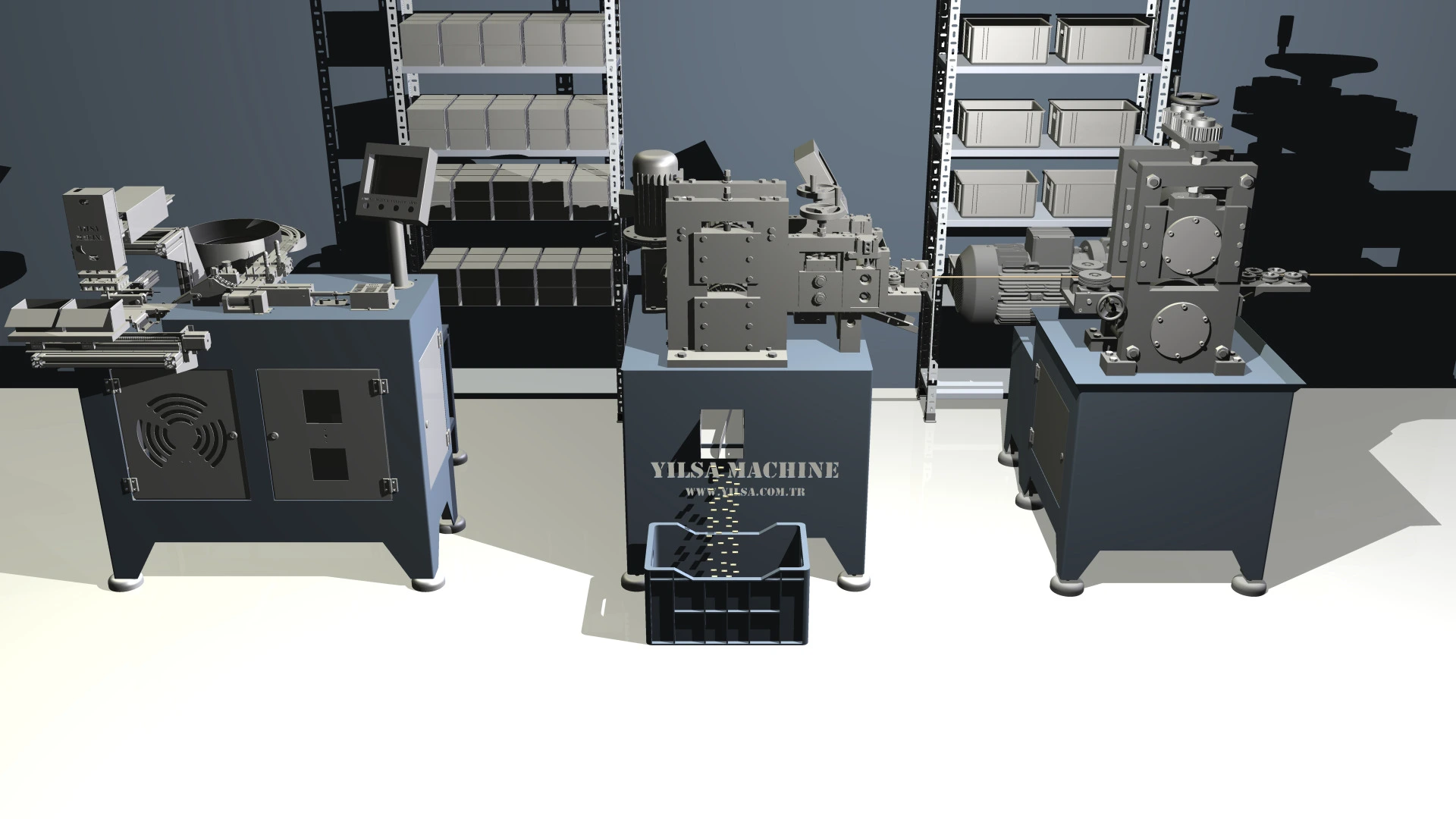

High-Precision Automated Production

Transform raw wheel weights into perfectly taped and packaged products with our integrated system capable of processing 90 kg per hour

Key Features & Technical Specifications

Taping and Packaging Machine

Lead-Free Wheel Weight production is ideal with our Taping and Packaging Machine. Steel wheel weights lined from the sorting drum pass through 5g/10g wheel weight channels to be arranged.

Wheel Weights are aligned on extra tape 5×4+10×4.

The wheel weight machine is adjustable for 5-5g and 5-10g, or can be produced only for 5-5g, which is more economical. Our company YILSA foresees this version to become a trend and recommends it.

As wheel weight machine producers, our machines produce extra blue tape 5g/10g wheel weights. Our machines can also use extra paper tape.

The automation of our Adhesive Wheel Weight Machine is developed by our own staff as a result of years of experience. Therefore, our wheel weight producing machines work smoothly and are user-experience focused.

Should not be confused with a Wheel Weight Die-Casting Machine. Our machines do not produce clip-on wheel weight or lead wheel weight.

They are suitable for wheel weights for aluminum wheels, motorcycle wheel weight, and truck wheel weight.

| Dimensions | 1158mm x 1058mm x 1380mm |

| Configuration | 5g+5g and 5g+10g configurations |

| Production Capacity | 90 kg/hr |

| Net Weight | 350 kg |

| Energy Consumption | 0.2 kWh/hr |

| Control System | Delta PLC with 7" Display |

| Packaging Capacity | 15 boxes/hr (with optional unit) |

Mastering Production Excellence

Our Taping and Packaging Machine stands at the forefront of wheel weight automation technology. This precision-engineered system transforms your production line, delivering perfectly finished products ready for market distribution.

System Features

Powered by advanced Delta PLC technology, our system offers unprecedented control over the finishing process. The intuitive 7" interface provides complete command over production parameters, while real-time monitoring ensures consistent quality across high-volume operations.

Advanced Features

- Dual Configuration System: Seamlessly switch between 5g+5g and 5g+10g formats

- Precision Control: Advanced Delta PLC system with intuitive interface

- Real-Time Monitoring: Live production tracking and adjustment

- Automated Quality Control: Consistent tape application and alignment

- Optional Integration: Synchronized packaging unit capability

- Energy Efficient Design: Optimized power consumption at 0.2 kWh/hr

Production Excellence

The system's innovative design combines high-speed production with precision quality control. The optional packaging unit integrates seamlessly with the taping process, creating a fully automated finishing line that transforms raw wheel weights into market-ready products.

Integration & Control

Every aspect of the production process is monitored and controlled through our advanced interface system. The machine's modular design allows for easy integration of the optional packaging unit, while the sophisticated control system ensures perfect synchronization between taping and packaging operations.

Performance Benefits

- Maximum Productivity: Process up to 90 kg per hour

- Superior Quality Control: Consistent tape application

- Flexible Configuration: Easy switching between weight combinations

- Efficient Packaging: Optional unit processes 15 boxes per hour

- User-Friendly Operation: Minimal training required

- Reliable Performance: Built for continuous operation

Contact Us

Transform your wheel weights production with our innovative solutions. Get in touch with us to discuss your requirements and discover how our solutions can benefit your business.

Contact us to become our representatives!