Transform Your Production Economics

Convert standard 8mm wire rod into precise 11.5 x 3mm flat steel, reducing raw material costs by up to 50% while streamlining your production process

Key Features & Technical Specifications

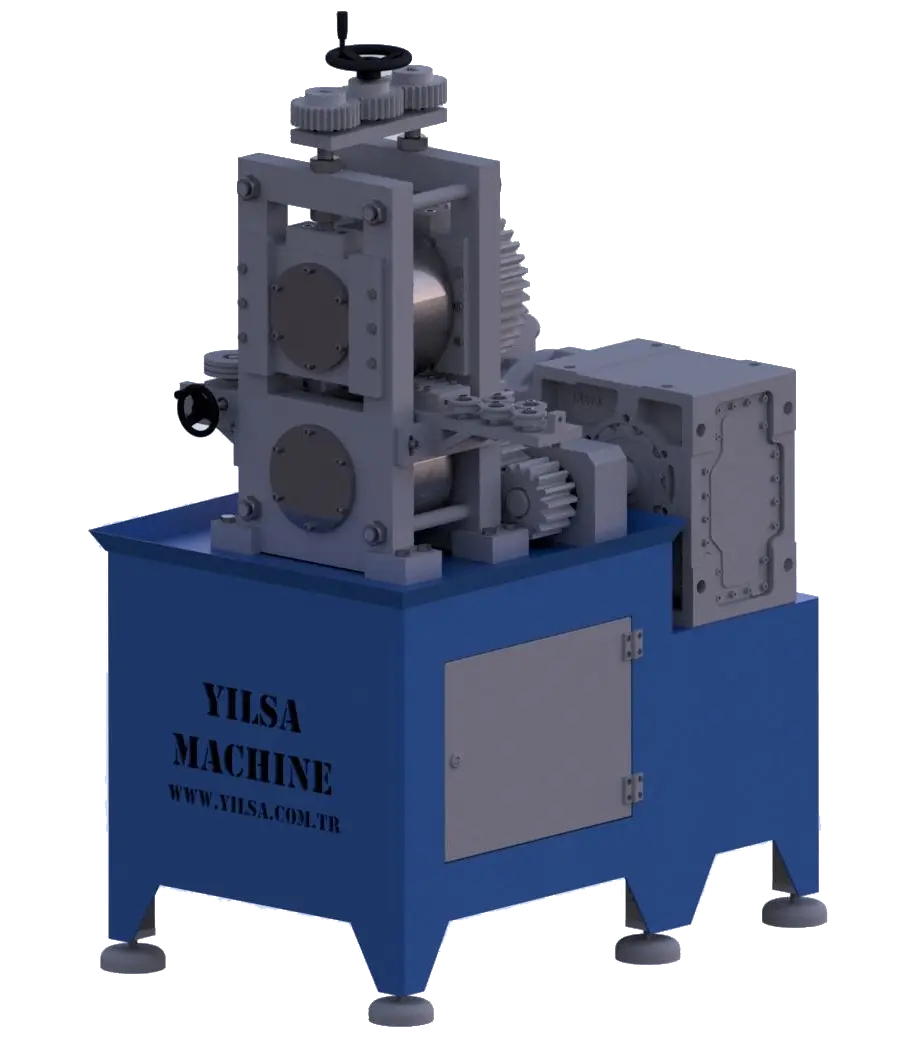

Wire Flattening Machine

Our Wire Flattening Machine transforms Φ8 1006 and 1008 grade wire rod into smooth 11.5×3 mm flat metal strips. The flattening process ensures the precision required for manufacturing Fe stick-on wheel weights and provides a smooth surface that improves the adhesion of pressure-sensitive tapes.

The strips produced by the Wire Flattening Machine play a critical role in ensuring that the manufactured adhesive stick-on wheel weights stay securely on the rim and maintain accurate wheel balancing.

This machine is not used in the production of lead clip-on wheel weights or rounded tire balance wheel weights.

It is ideal for manufacturing straight corner wheel weights Fe sticker, Fe/steel/iron adhesive wheel balance weights, and zinc-coated wheel weights.

| Power System | Power System: 11 kW AC Motor |

| Production Speed | Production Speed: 16 m/min |

| Machine Dimensions | Machine Dimensions: 80cm Width x 120cm Length x 180cm Height |

| Machine Weight | Machine Weight: 1000 kg |

| Input Material | Input Material: 8mm Wire Rod |

| Output Product | Output Product: 11.5 x 3mm Flat Steel |

Purpose-Built Innovation

Wire Flattening and Shaping: The First Step in Precision Adhesive Wheel Weight Manufacturing

The Wire Flattening Machine is the essential first step in the Adhesive Wheel Weight Production Line, transforming raw fi8 wire rod into flat, uniform metal strips. This process ensures that the material is properly prepared for the subsequent chopping, marking, taping, and packaging stages.

While global manufacturers like FENN Torin (USA) and Maschinenfabrik NIEHOFF (Germany) offer high-speed flattening technologies for a broad range of industries, our specialized system is exclusively designed for the production of adhesive wheel weights. Unlike multi-purpose flattening mills, our machine is optimized for:

- High surface quality to ensure optimal adhesive bonding

- Consistent strip thickness and width for precise die-cutting

- Easy integration with downstream automation

Inspired by global standards but tailored to your specific application, our solution combines cost efficiency, local service, and high-performance output—offering an ideal balance for businesses focused on wheel weight production.

Contact Us

Transform your wheel weights production with our innovative solutions. Get in touch with us to discuss your requirements and discover how our solutions can benefit your business.

Contact us to become our representatives!